Parker Domnick Hunter OIL-X OVR

Series Compressed Air Filters

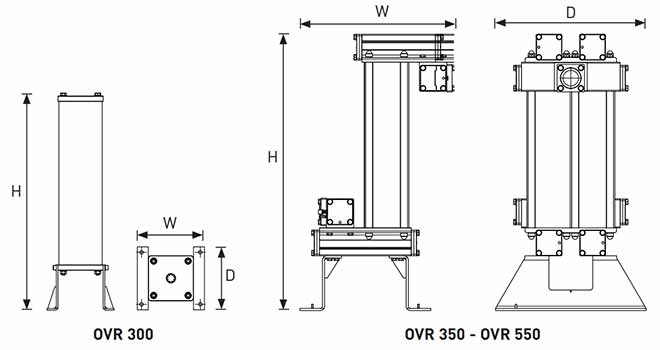

OIL-X OVR Oil Vapor Removal filters are designed to reduce oil vapor and also overcome the issues of traditional loose filled carbon towers.

Manufactured from extruded aluminium, the Parker Domnick Hunter OIL-X OVR is smaller and lighter than equivalent carbon towers. Compact activated carbon cartridges utilise a unique filling technique to maximise packing density of the adsorbent bed. Retained to prevent movement, 100% of the activated carbon bed is then utilised during operation, guaranteeing performance, whilst the heavy attrition, dusting and blocked particulate filters associated with carbon tower designs is eliminated. The use of cartridges also provides trouble free maintenance, reducing system downtime.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

Compact, modular construction oil vapor removal filters designed to reduce oil vapor when industrial applications require compressed air to meet ISO8573-1 Class 0 or Class 1.

Oil free plant air can be affected by many factors such as pressure, temperature, air flow, oil concentration and humidity. The OIL-X OVR selection process considers all of these factors to ensure consistent outlet air quality over 12 months of continuous operation.

Features & Benefits of Parker Domnick Hunter OIL-X OVR Series Compressed Air Filters:

• Suitable for use with oil lubricated and oil-free compressors

• Tested in accordance with ISO8573-5 and 3rd party performance validated by Lloyds Register

• Can be installed in the compressor room for plant scale protection, at point of use to protect critical applications (or both if old, contaminated piping is in use)

• FDA Title 21 compliant & EC1935 exempt

• Unique adsorbent fill technique

• Large capacity bed reduces the number of units required but still offers a compact and light weight design with flexible inlet / outlet connectivity

• Simple, easy maintenance

Sizing and Selection

To ensure quoted air purity specification is met, more than one filtration grade may be required.

Important Note: For quoted air purity performance, compressed air filters must be sized correctly for minimum operating pressure and maximum inlet flow rate using the correction factors found in the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

*Scroll to the right to see entire chart on mobile.

*Scroll to the right to see entire chart on mobile.

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View