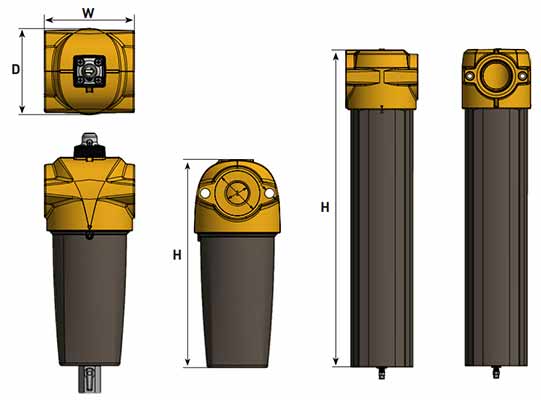

Parker Domnick Hunter OIL-X AAP

Series Compressed Air Filters

Parker Domnick Hunter high efficiency coalescing and dry particulate filters with very low pressure drop providing excellent energy savings.

OIL-X filters incorporate a number of unique and patented design features to minimise differential pressure and provide a filter and element combination where the differential pressure starts low and stays low to maximise energy savings and provide the lowest lifetime costs without compromising air quality.

Grade AAP Coalescing Liquids and Particle Removal in Compressed Air or Gaseous Nitrogen. Particle Removal down to 0.01 micron Max Remaining Oil Content 0.01mg/m3 delivering Filtration of 99.9999% Initial Dry Differential Pressure <70mbar (1.0 psi) Initial Saturated Pressure drop <125mbar (1.8psi)

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

The Parker domnick hunter OIL-X range of cast aluminium range compressed air filters has been designed from the outset to meet the air quality requirements of all editions of ISO8573-1, when validated in accordance with the stringent requirements of ISO12500-1.

An efficient and cost effective manufacturing process is a major factor in maintaining the profitability and growth of your business. All Parker domnick hunter products are designed to not only minimise the use of compressed air and electrical energy in their operation, but also to significantly reduce the operational costs of the compressor by minimising pressure losses.

Features & Benefits of Parker Domnick Hunter OIL-X Series Compressed Air Filters:

• For the removal of bulk liquid, water and oil aerosols, atmospheric dirt and solid particles, rust, oil vapor, pipescale and micro-organisms

• Coalescing filter performance tested to the stringent requirements of ISO12500-1, ISO8573-2 and ISO8573-4

• Dry particulate filter performance tested in accordance with the requirements of ISO8573-4

• Highest air quality

• Lowest operational differential pressure

• Lowest energy consumption

• Lowest CO2 emissions

• Low total cost of ownership

Sizing and Selection

To ensure quoted air purity specification is met, more than one filtration grade may be required.

Important Note: For quoted air purity performance, compressed air filters must be sized correctly for minimum operating pressure and maximum inlet flow rate using the correction factors found in the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

*Scroll to the right to see entire chart.

To correctly select a filter model, the flow rate of the filter must be adjusted for the minimum operating pressure of the system.

1 Obtain the minimum operating pressure and maximum compressed air flow rate at the inlet of the filter.

2 Select the correction factor for minimum operating pressure from the CFP table (always round down e.g. for 5.3 bar, use 5 bar correction factor)

3 Calculate the minimum filtration capacity: Minimum Filtration Capacity = Compressed Air Flow Rate x CFP.

4 Using the minimum filtration capacity, select a filter model from the flow rate tables (filter selected must have a flow rate equal to or greater than the minimum filtration capacity).

5 AA models are supplied with a float drain as standard. For pressures of 232 to 290 psi g (16 to 20 bar g ), a manual drain must be used.

*Scroll to the right to see entire chart.

MUST HAVE Manual Drain Order "MX" Option

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View