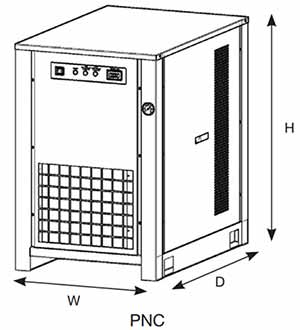

PNC Series Non-Cycling Refrigeration Air Dryers

Parker PNC Series Non-Cycling Refrigerated Air Dryer offers clean/dry air, designed to reduce operational costs of a compressor by minimizing pressure loss. PNC Series Non-Cycling Refrigerated Air Dryers guarantee performance and superior efficiency.

Costly contamination problems can be avoided by installing a PNC Series non-cycling refrigerated dryer (ranging from 200 - 1200 cfm).

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

Parker’s 4-in-1 heat exchanger offers minimal pressure drops and class leading performance, and significantly increases the efficiency of the whole compressed air treatment process.

Compressed air purification equipment must deliver uncompromising performance and reliability while providing the right balance of air quality with the lowest cost of operation. Many manufacturers offer products for the filtration and purification of contaminated compressed air, which are often selected only upon their initial purchase cost, with little or no regard for the air quality they provide, the cost of operation throughout their life or their environmental impact. When purchasing purification equipment, delivered air quality, the overall cost of ownership and the equipment's environmental impact must always be considered.

Features of Parker PNC Series Air Dryers:

• Optimum dewpoint levels for highest system performance

• Unique 4-in-1 heat exchanger

• High reliability, easy to use and maintain

• Environmentally friendly

• Extremely low pressure drop design

• Easy to use, highly reliable control panel

• ETL listed

• Visual indication of dewpoint performance

• High and low refrigerant pressure alarm light

• Lighted On/Off switch

• Crankcase heater prevents refrigerant

migration into compressor oil which provides

compressor lubrication integrity, both prior to start-up and during the “off” cycle

• Oversized condenser to operate in ambient to 115˚F (45˚C) with pre-filter

• Dryers manufactured in facility certified to ISO9001 and ISO14001

• High efficiency Parker Pre-Filter recommended on all models

• Unique design allows for easy filter and bypass install

• CRN registered all provinces

Reduced Indirect Costs

Electricity required by the compressor to compensate for pressure drops in the air dryer accounts for around 25% of its total cost over 5 years. Parker's PNC Series offers average pressure drops which are about one half those of conventional systems.

Lowest Differential Pressure

Parker refrigerated dryers offer the lowest differential pressure with an average of 2.0 psid versus the industry average of 5.0 psid.

Example cost of power savings for a 500 scfm dryer operating at 8,760 hours per year:

$0.05 per KW = $546 per year

$0.10 per KW = $1091 per year

$0.15 per KW = $1638 per year

PNC Series are designed to significantly reduce the operational costs of the compressor by minimizing pressure loss.

Reduced CO2 Emissions

Many countries worldwide are looking closely at their manufacturing industries in an effort to reduce the amount of harmful greenhouse gases released into the atmosphere. The use of electricity has a direct impact on the generation and release of CO2. By significantly reducing the energy consumption of its products, Parker can help you reduce your carbon footprint and protect the environment.

Environmentally Friendly

Montreal Protocol compliant R404a (PNC Series) refrigerants allow for zero ozone depletion, low global warming potential and low refrigerant charge.

Heat Exchanger provides less than 2 psi pressure drop

The heat exchanger features an extremely robust, all-in-one aluminum design, with no interconnecting tubing. The flow path of the heat exchanger has been designed in order to optimize its performances. In particular, large volumes allow low air velocity through the heat exchanger section, resulting in high exchange efficiency and low pressure drops. Pressure drops are further improved thanks to the absence of interconnecting pipes through the different sections of the heat exchanger and to a straight forward path of the compressed air flow with smooth and minimum changes of flow directions.

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

*Scroll to the right to see entire chart.

*Scroll to the right to see entire chart.

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View