P3TJ MODUFLEX Regenerative Desiccant Air Dryer

The Parker P3TJ Moduflex Dry Air System range of regenerative desiccant air dryers offers the user uncompromised performance from a dedicated “point of use” Clean Dry Air system. It is easy to install and will transform an ordinary process into a highly reliable and efficient production operation. The P3TJ Dry Air System has been designed with “quick change” filter, dryer combi-cartridges and in-line air connections to facilitate easy maintenance.

P3TJ heatless air dryers totally clean and dry compressed air down to –40°C pdp. Easy to install, the P3TJ Dry Air System has been designed with quick-change filter, dryer combi-cartridges & inline air connections to facilitate easy maintenance.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

The P3TJ Dry Air System totally cleans and dries compressed air down to –40°C (–40°F) pressure dewpoint; for critical applications, a pressure dewpoint of –70°C (–100°F) is achievable. The principles of the P3TJ Dry Air System are based upon well proven concepts which embody true innovation and excellent value for money with technically superior yet simple design, while leading the way in compressed air drying.

Features & Benefits of Parker P3TJ MODUFLEX Air Dryer:

• Point Of Use Application - Bringing Clean Dry Air just where you need it.

• Approved to International Standards - Designed in accordance with ASME VIII Div.1, approved to CSA/UL/CRN and fully CE Marked (PED, EMC, LVD) as standard.

• Simple to install - Flexible installation utilising the multiple in-line inlet & outlet connection ports.

• Compact and lightweight - Can be Floor, Bench or Wall/Canopy mounted.

• Very Quiet Operation - Noise level less than 70dB(A).

• Can be installed almost anywhere - IP66 / NEMA 4 protection as standard.

• Audible alarm - Indicating Service interval for optimal performance.

• Simple & easy to maintain - A 100% service can be achieved insitu in under 15 minutes due to the quick release top cap arrangement, which does NOT require the inlet / outlet ports to be disconnected as with traditional systems.

Sizing and Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

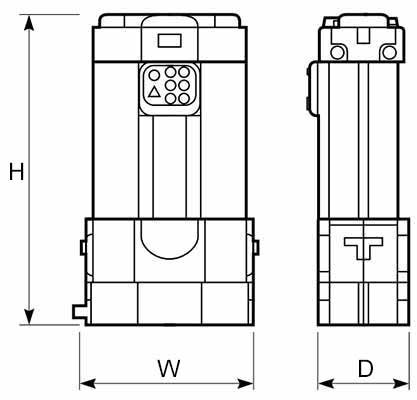

Dimensions and Weight *Scroll to the right to see the entire chart on mobile

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View