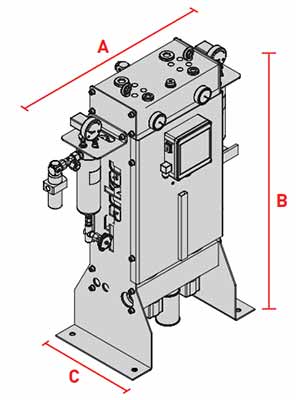

HDK-MT 15/100-70/100 Series Desiccant High Pressure Compressed Air Dryers

The patent protected HDK-MT concept is unique in its compact design. HDK-MT combines a vibration resistant, torsion rigid dryer unit, made of high precision vessel pipes and valve blocks, with a pre-stressed filling of highly active desiccant beads.

For applications requiring high pressure compressed air or nitrogen gas up to 100 bar with volume flows of up to 650m³/h and pressure dew points down to -40°C.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

HDK-MT dryers come mounted with GH series filters, incorporating tie-rod fixed filter elements, which provide almost no target for torsional forces and abrasion. This provides a safe, reliable, and robust operation under pressure variations and constant vibration, typical for discontinuous operation in high pressure ranges.

The choice of corrosion resistant materials, like the hard coated aluminium valve blocks, seamless vessels and stainless steel fittings make HDK-MT series dryers ideally suited for harsh environments.

Compact and robust in design HDK-MT dryers are ideally suited for installations in tight spaces, like compressor skids, as well as installations on ships, platforms, and in containers.

Features & Benefits of Parker Zander HDK-MT 15/100-70/100 Series Air Dryers:

• Dew-point control as standard

• Compact, unique patent protected design of the pressure envelope

• Pulsation and vibration resistant

• Corrosion resistant

• Small footprint

• Simple servicing

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the correction factors found in the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View