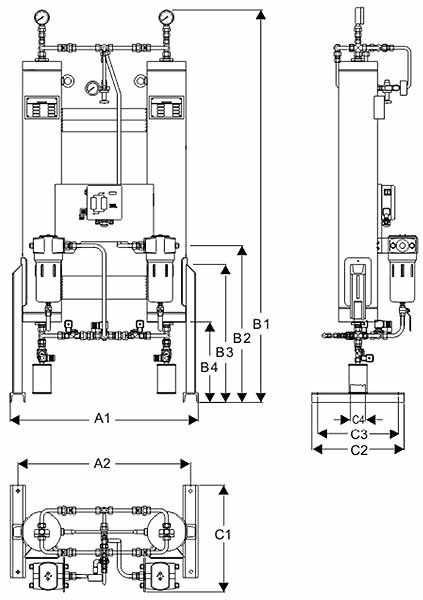

HDK 50 Series Adsorption Air Dryers

The Parker Zander HDK 50 bar range of high pressure compressed air dryers are designed to dry compressed air and gaseous nitrogen at high pressure levels of up to 50 bar reliably and efficiently down to a pressure dew point of -40°C. HDK series dryers come equipped with integrated Parker Zander pre- and after filtration and are capable of volume flows up to 1180 m³/h.

For applications requiring high pressure compressed air or nitrogen gas up to 50 bar with volume flows of up to 1180m³/h and pressure dew points down to -25/-40°C.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

Typical applications for HDK 50 series high pressure compressed air dryers are in power stations (i.e. start up of diesel generators) as well as marine applications (i.e. tank ventilation, rope tensioning on off-shore rigs, generator start up etc.).

Features & Benefits of Parker Zander HDK 50 Series Air Dryers:

• Pressure dew point down to -40°C

• Volume flows up to 1180 m³/h @ 50 bar g (725.19 psi g)

• Pre- and after filters installed as standard

Scope of Supply

• Ready to install high pressure adsorption dryer including dew-point control and mounted pre-and after filter

• Optional equipment available mounted ex-works

Available Accessories

• Start-up device

• High pressure differential pressure gauges for the filters

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the correction factors found in the product information sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View